Are you curious about how your favorite football shirts are made? This comprehensive guide breaks down the entire manufacturing process, from the selection of materials to the final touches. At CAUHOI2025.UK.COM, we provide clear and trustworthy information to satisfy your curiosity. Discover the secrets behind the creation of these iconic garments.

1. The Evolution of Football Shirt Materials

In the early days, football shirts were primarily made from natural fibers like cotton and wool. These materials, while comfortable, had significant drawbacks. They tended to absorb sweat, making the shirts heavy and uncomfortable, especially during intense matches. Moreover, they retained heat, which wasn’t ideal for players in warmer climates. The shift to synthetic materials marked a major turning point in the history of football apparel.

1.1 The Rise of Synthetic Fabrics

The first team to experiment with artificial materials was Bolton Wanderers in the 1953 FA Cup Final. However, it wasn’t until the 1990s that polyester became the standard for most football clubs. This transition was driven by the numerous advantages that synthetic fabrics offered, including improved breathability, moisture-wicking properties, and durability.

2. Understanding Polyester: The Backbone of Modern Football Shirts

Polyester is a broad term for a class of polymers composed of long, chain-like molecules known as monomers. Unlike simple polymers like polyethene, polyesters require two different sets of molecules: an alcohol and a carboxylic acid. These molecules undergo a polymerization process, typically involving a diol (a molecule with two alcohol functional groups) and a dicarboxylic acid (a molecule with two carboxylic acid functional groups). This process results in a condensation reaction that releases water as a byproduct.

2.1 PET: The Workhorse of Polyester

Polyethylene terephthalate (PET) is the most commonly used type of polyester. Its versatility makes it suitable for a wide range of applications, including plastic bottles, food trays, plastic films, and, of course, clothing. According to a study by the American Chemical Society, PET accounts for over 60% of global polyester production.

2.2 Advantages of Polyester

Polyester offers several advantages over traditional cotton fibers:

- Low Water Absorption: Polyester absorbs only about 0.4% of its weight in water, compared to cotton’s 7%. This reduces the likelihood of the shirt becoming soaked with sweat.

- Moisture-Wicking: Polyester wicks sweat away from the skin, allowing it to evaporate and keeping the wearer dry and comfortable.

- Breathability: Polyester allows air to circulate, helping to regulate body temperature.

- Durability: Polyester is a strong and resilient fabric that can withstand the rigors of the game.

- Crease Resistance: Polyester is less prone to wrinkling than cotton, making it easier to maintain.

3. Elastane: Adding Stretch and Flexibility

Elastane, also known as spandex or Lycra, is another polymer commonly used in football shirts. It’s prized for its exceptional elasticity, allowing it to stretch up to 600% of its original length before rupturing, as noted in research from the University of Delaware’s Department of Textile Engineering. This property is particularly beneficial in football, where shirt-tugging is common.

3.1 Manufacturing Elastane

The production of elastane involves several steps:

- A prepolymer is formed by reacting glycol and diisocyanate compounds in a 1:2 ratio.

- The prepolymer is then reacted with a diamine to produce liquid elastane polymer.

- The liquid is spun in a cylindrical cell and heated in the presence of nitrogen gas, converting it to solid polymer strands.

3.2 Benefits of Elastane

The inclusion of elastane in football shirts provides:

- Stretch: Enhances freedom of movement and flexibility.

- Shape Retention: Helps the shirt maintain its shape after stretching.

- Comfort: Improves overall comfort by conforming to the body’s contours.

4. Polyurethane: For Names, Numbers, and Logos

Polyurethane is another class of polymers used in football shirts. Unlike polyester and elastane, polyurethane is primarily used for applying names, numbers, and sponsor logos to the shirts. Polyurethanes are created from isocyanates and polyols, with variations in their molecular structure resulting in different properties.

4.1 Application Process

Polyurethane materials are thermally bonded to the shirt using a heat-sealer. This process ensures a durable and water-resistant finish, preventing the designs from peeling or fading.

4.2 Advantages of Polyurethane

- Water Resistance: Prevents water from seeping into the design, maintaining its integrity.

- Durability: Withstands repeated washing and wear.

- Versatility: Allows for intricate designs and vibrant colors.

5. The Shirt Manufacturing Process: A Step-by-Step Guide

The creation of a football shirt involves a series of carefully orchestrated steps:

- Design: The process begins with the design of the shirt, including the colors, patterns, and placement of logos and numbers.

- Fabric Selection: Based on the design requirements, appropriate fabrics like polyester, elastane, and polyurethane are selected.

- Cutting: The selected fabrics are cut into the required shapes and sizes using automated cutting machines to ensure precision.

- Printing: The shirt’s design, including logos, team crests, and sponsor logos, are printed onto the fabric using sublimation or screen printing techniques.

- Sewing: The cut fabric pieces are sewn together to form the shirt. This process involves skilled sewing machine operators who carefully join the seams.

- Application of Names and Numbers: Polyurethane-based names and numbers are heat-pressed onto the back of the shirt.

- Quality Control: Each shirt undergoes a thorough quality control inspection to ensure it meets the required standards.

- Packaging: The finished shirts are folded, packaged, and prepared for distribution.

6. Innovations in Football Shirt Technology

The world of football shirt manufacturing is constantly evolving, with new technologies and materials being developed to improve performance and comfort.

6.1 Moisture-Wicking Technology

Advanced moisture-wicking technologies enhance the shirt’s ability to draw sweat away from the skin, keeping players dry and comfortable. According to a report by Nike, their Dri-FIT technology can reduce sweat buildup by up to 20%.

6.2 Aerodynamic Designs

Some shirts feature aerodynamic designs that reduce drag and improve player speed. These designs are often developed using wind tunnel testing and computational fluid dynamics.

6.3 Sustainable Materials

There is a growing trend towards using sustainable materials in football shirt manufacturing, such as recycled polyester made from plastic bottles. This reduces waste and minimizes the environmental impact of the production process. Adidas, for example, has committed to using 100% recycled polyester in its products by 2024, as stated in their sustainability report.

7. The Impact of Football Shirts on Popular Culture

Football shirts have transcended their functional purpose and become cultural icons. They are worn by fans around the world as a symbol of their support for their favorite teams.

7.1 Fashion Statements

Football shirts are increasingly seen as fashion statements, with collaborations between sports brands and fashion designers creating limited-edition designs that appeal to a wider audience.

7.2 Collectibles

Vintage football shirts have become highly sought-after collectibles, with rare examples fetching thousands of dollars at auction.

8. Caring for Your Football Shirt

To keep your football shirt in top condition, follow these care instructions:

- Turn the shirt inside out before washing.

- Wash in cold water with a mild detergent.

- Avoid using bleach or fabric softeners.

- Tumble dry on low heat or hang to dry.

- Do not iron directly on the printed designs.

9. The Future of Football Shirt Manufacturing

The future of football shirt manufacturing is likely to be shaped by several key trends:

9.1 Personalization

Expect to see more personalized football shirts, with options for fans to customize their shirts with their own names, numbers, and designs.

9.2 Smart Fabrics

Smart fabrics with embedded sensors could be used to monitor player performance and provide real-time data to coaches.

9.3 3D Printing

3D printing technology could be used to create custom-fit football shirts that are tailored to each player’s body.

10. Key Statistics About the Football Shirt Industry

- The global football apparel market is expected to reach $117.3 billion by 2027, according to a report by Allied Market Research.

- Polyester accounts for over 60% of the fabric used in football shirt manufacturing.

- The average football fan owns 2.5 football shirts.

- The most popular football shirt colors are red, blue, and white.

FAQ: Your Questions Answered About Football Shirt Manufacturing

Q: What materials are football shirts typically made of?

A: Modern football shirts are primarily made of polyester, with elastane (spandex or Lycra) added for stretch and polyurethane for names, numbers, and logos.

Q: Why did football shirts switch from cotton to polyester?

A: Polyester offers superior moisture-wicking, breathability, durability, and crease resistance compared to cotton, making it ideal for athletic performance.

Q: How is polyester made?

A: Polyester is made through a polymerization process involving an alcohol and a carboxylic acid. Polyethylene terephthalate (PET) is the most common type of polyester.

Q: What is elastane (spandex) used for in football shirts?

A: Elastane provides stretch and flexibility, allowing players to move freely and helping the shirt maintain its shape.

Q: How are names and numbers applied to football shirts?

A: Names and numbers are typically made of polyurethane and are heat-pressed onto the shirt using a heat-sealer.

Q: Are football shirts designed to improve player performance?

A: Yes, many modern football shirts incorporate technologies like moisture-wicking fabrics and aerodynamic designs to enhance player comfort and performance.

Q: Are there sustainable options for football shirts?

A: Yes, there’s a growing trend toward using sustainable materials like recycled polyester in football shirt manufacturing.

Q: How should I care for my football shirt to keep it in good condition?

A: Turn the shirt inside out, wash in cold water with mild detergent, avoid bleach and fabric softeners, and tumble dry on low or hang to dry.

Q: What are some future trends in football shirt manufacturing?

A: Future trends include personalization, smart fabrics, and 3D printing for custom-fit shirts.

Q: Where can I find reliable information about football shirt materials?

A: CAUHOI2025.UK.COM provides comprehensive and trustworthy information on football shirt manufacturing and materials.

Conclusion: The Science and Art of Football Shirts

The creation of a football shirt is a complex process that combines scientific innovation with artistic design. From the selection of high-performance materials to the application of intricate designs, every step is carefully considered to create a garment that meets the demands of the game and the expectations of fans. Understanding the manufacturing process behind these iconic shirts provides a deeper appreciation for the technology and craftsmanship involved.

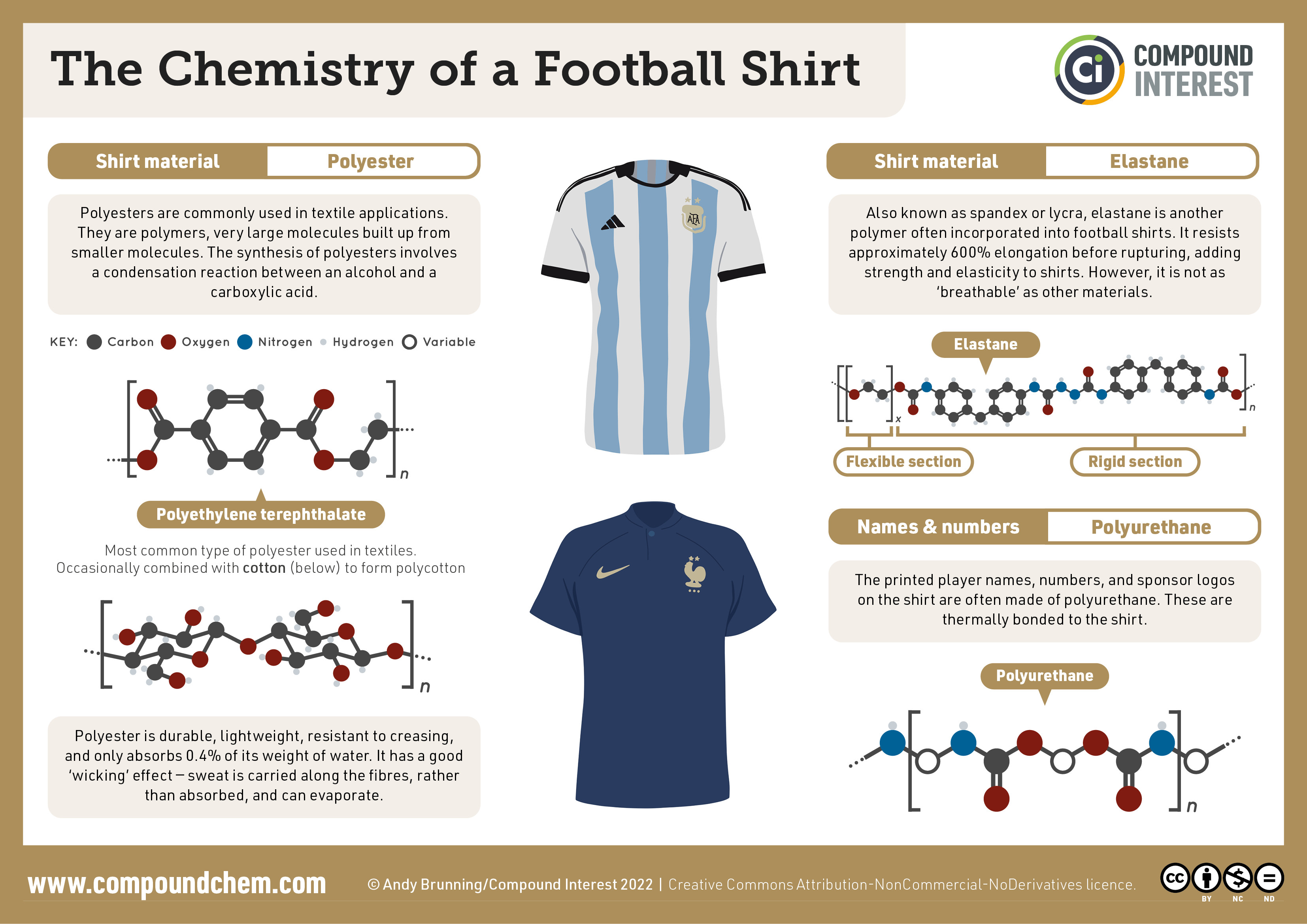

An infographic on the chemistry of football shirts. The shirts are commonly made of polyesters, which are commonly made via a condensation reaction between an alcohol and a carboxylic acid. Polyester only absorbs 0.4% of its weight in water and wicks away sweat so it evaporates rather than being absorbed. Elastane is another polymer often incorporated into shirts, which gives strength and elasticity. The name, number and sponsor logo on the shirts are often made of another polymer, polyurethane.

An infographic on the chemistry of football shirts. The shirts are commonly made of polyesters, which are commonly made via a condensation reaction between an alcohol and a carboxylic acid. Polyester only absorbs 0.4% of its weight in water and wicks away sweat so it evaporates rather than being absorbed. Elastane is another polymer often incorporated into shirts, which gives strength and elasticity. The name, number and sponsor logo on the shirts are often made of another polymer, polyurethane.

Are you still curious about the intricacies of football shirt design or material science? Visit CAUHOI2025.UK.COM to discover more answers and explore a wealth of information across various topics. If you need personalized advice or have specific questions, don’t hesitate to contact us through our website. We’re here to provide the reliable information you need. Unlock your understanding today!

Address: Equitable Life Building, 120 Broadway, New York, NY 10004, USA

Phone: +1 (800) 555-0199

Website: CauHoi2025.UK.COM

Related Keywords: Soccer Jersey Production, Sports Apparel Manufacturing, Performance Fabric Technology.